Bachelor‘s Thesis / OCT 2024 - FEB 2024

Pforzheim School of Design, Germany

BA Industrial Design

BIOFABRICATION

xxx

xxx

Mentored by:

Prof. Simone Sommer

Prof. Manuel Aydt

The textile industry is a major contributor to the planetary boundaries being exceeded each year.

Bacterial Filamentation as a regenerative design research project envisions a future in which circular

materials are bio-manufactured with a minimal consumption of resources by living organisms, thereby

counteracting the overuse of planetary resources.

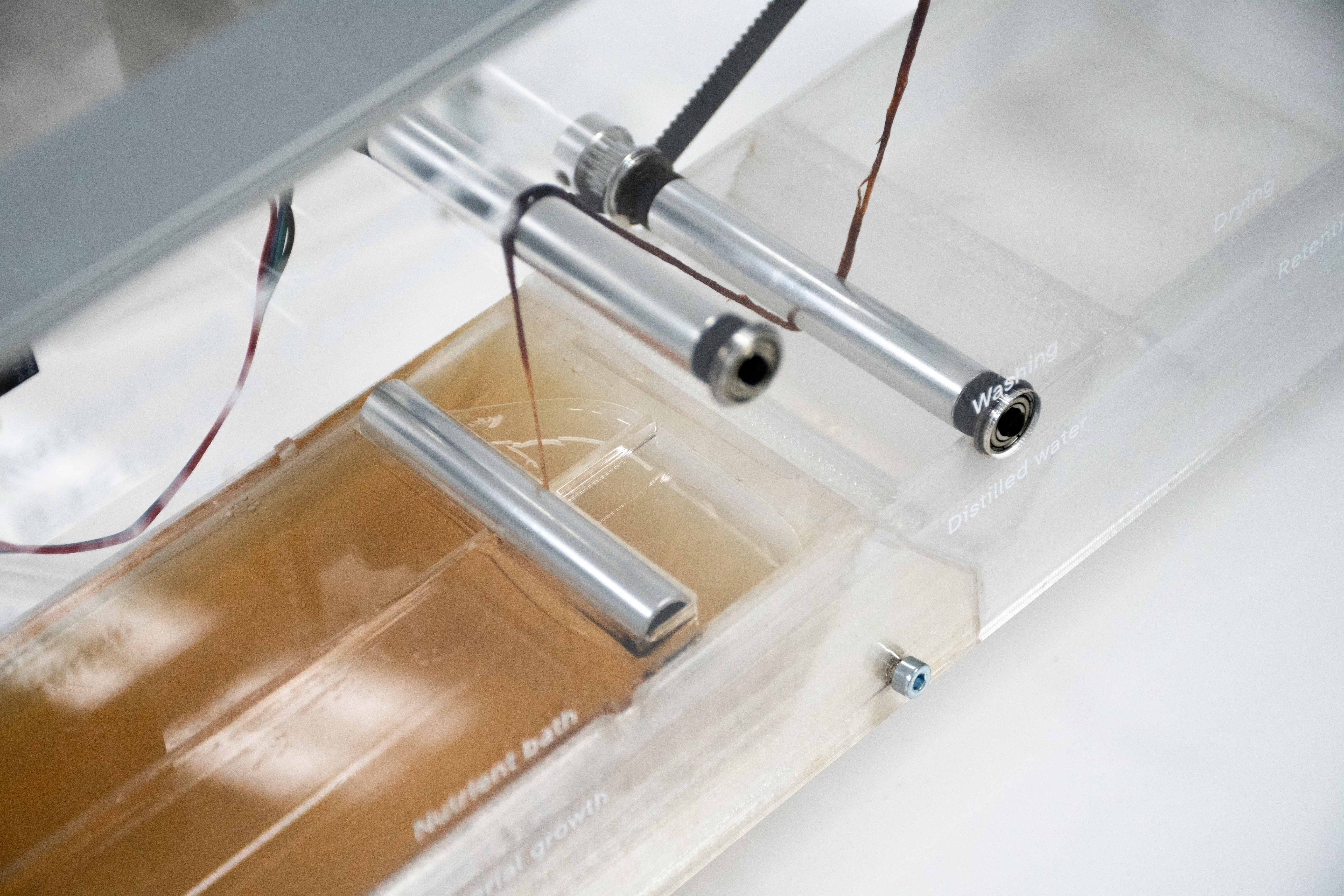

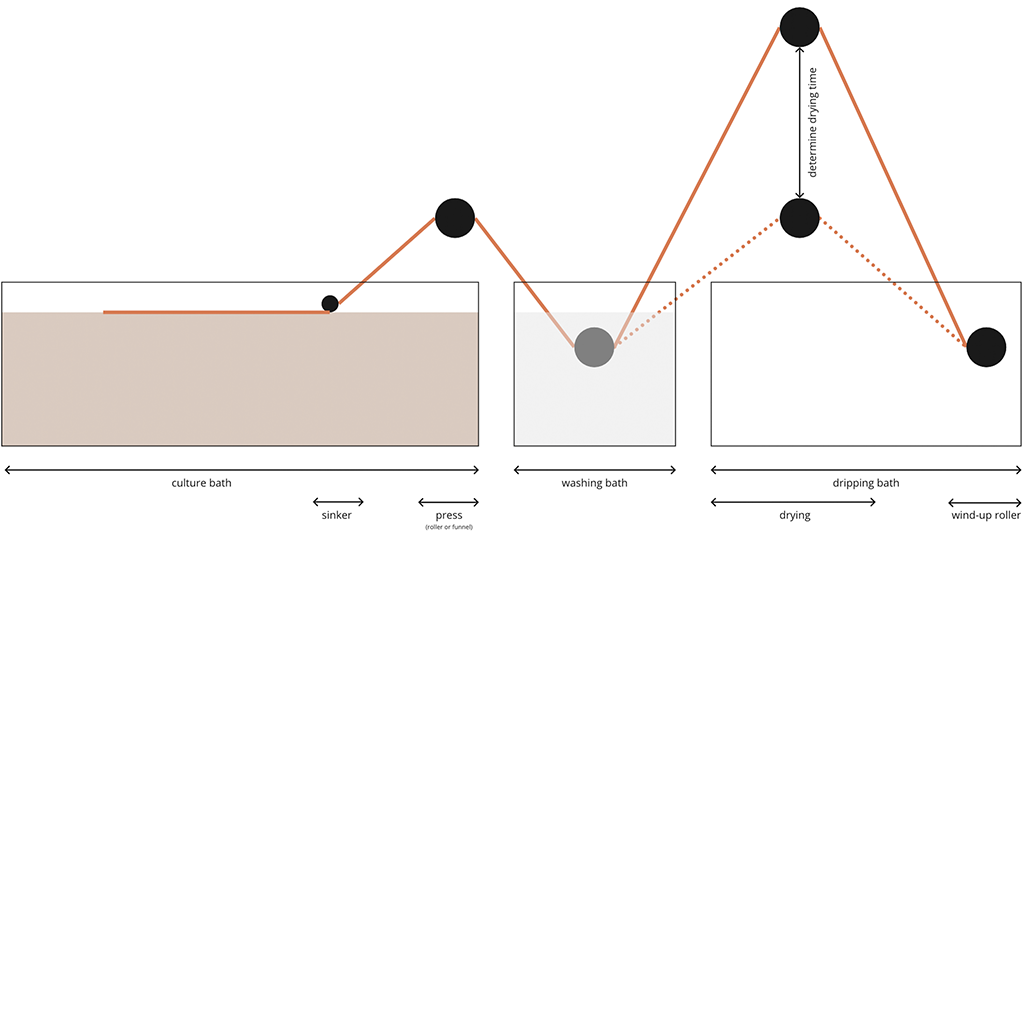

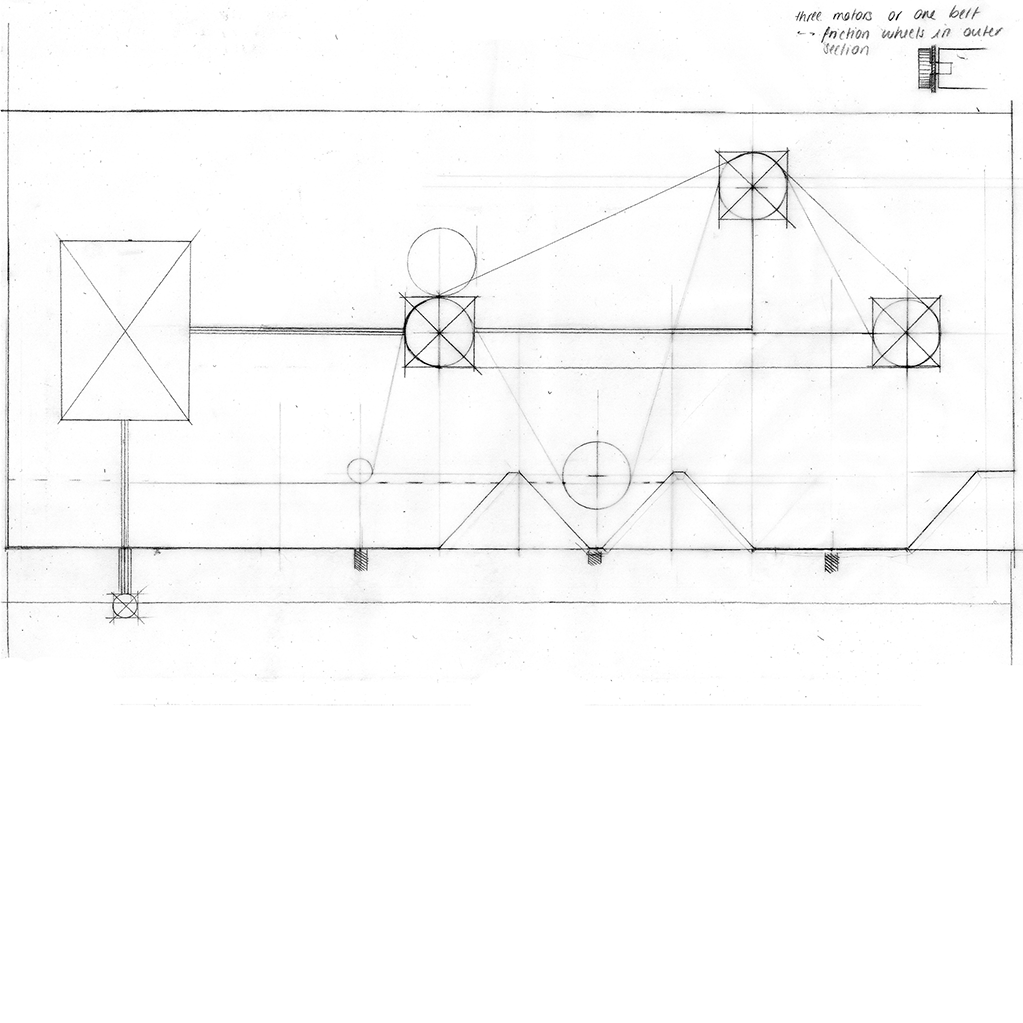

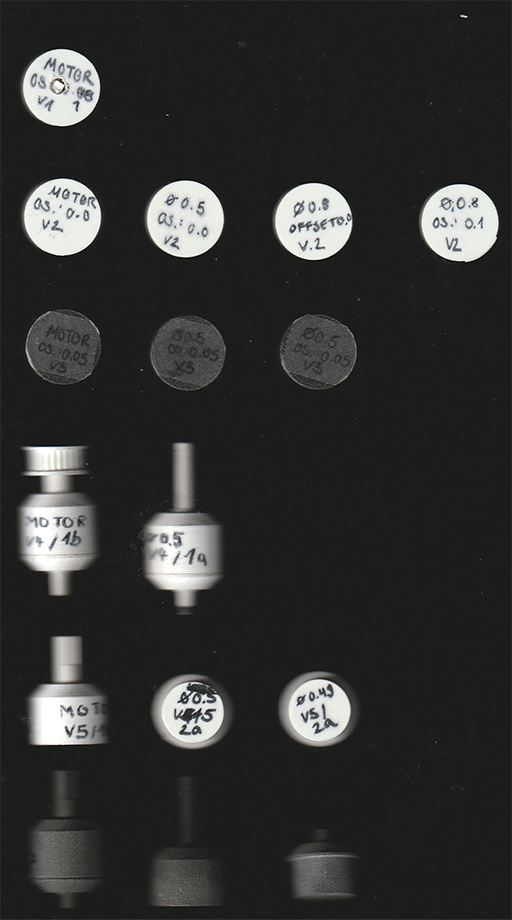

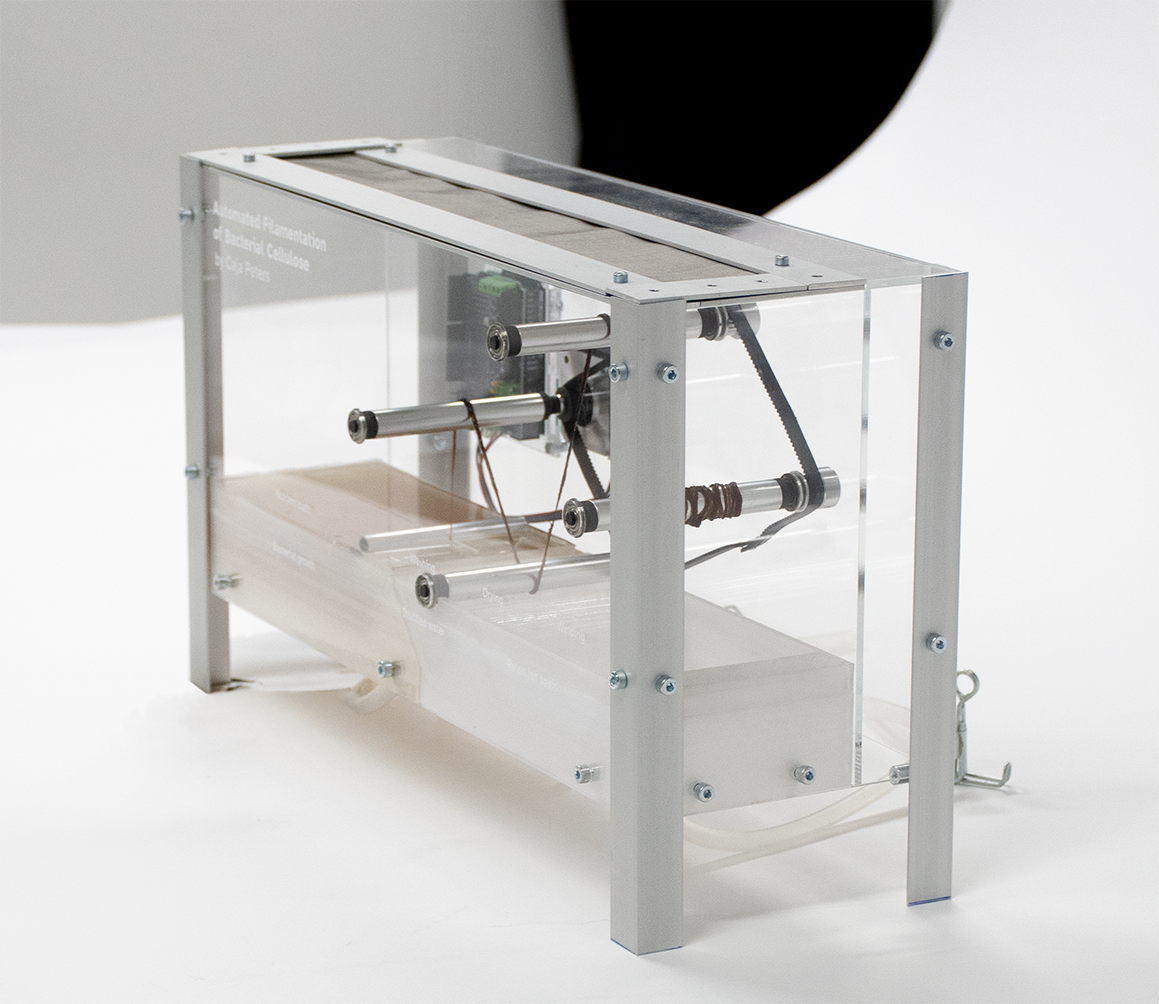

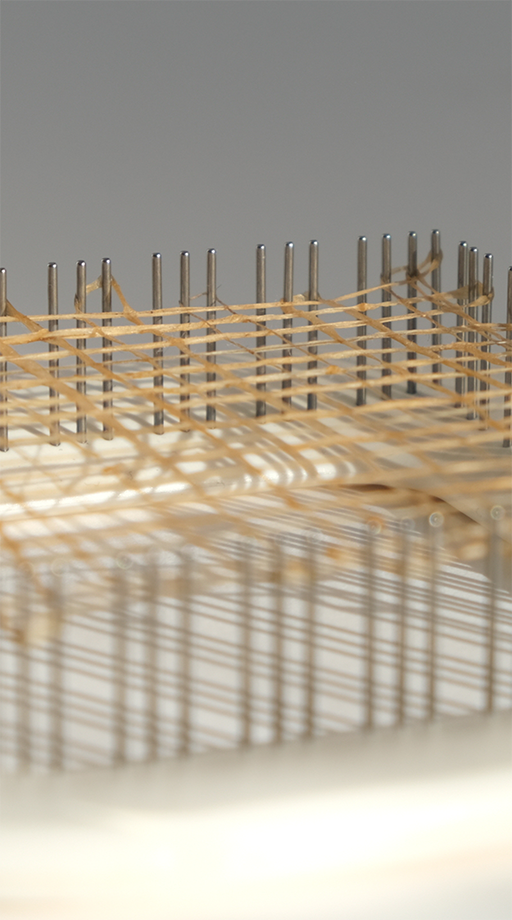

In an automated process, a yarn-like filament made from bacterial cellulose is fermented, harvested,

washed, dried and wound up. The filament can be used to produce textiles, which have been explored through

weaving and show potential areas of applications—reinforcements, upper materials, soles, but also any type

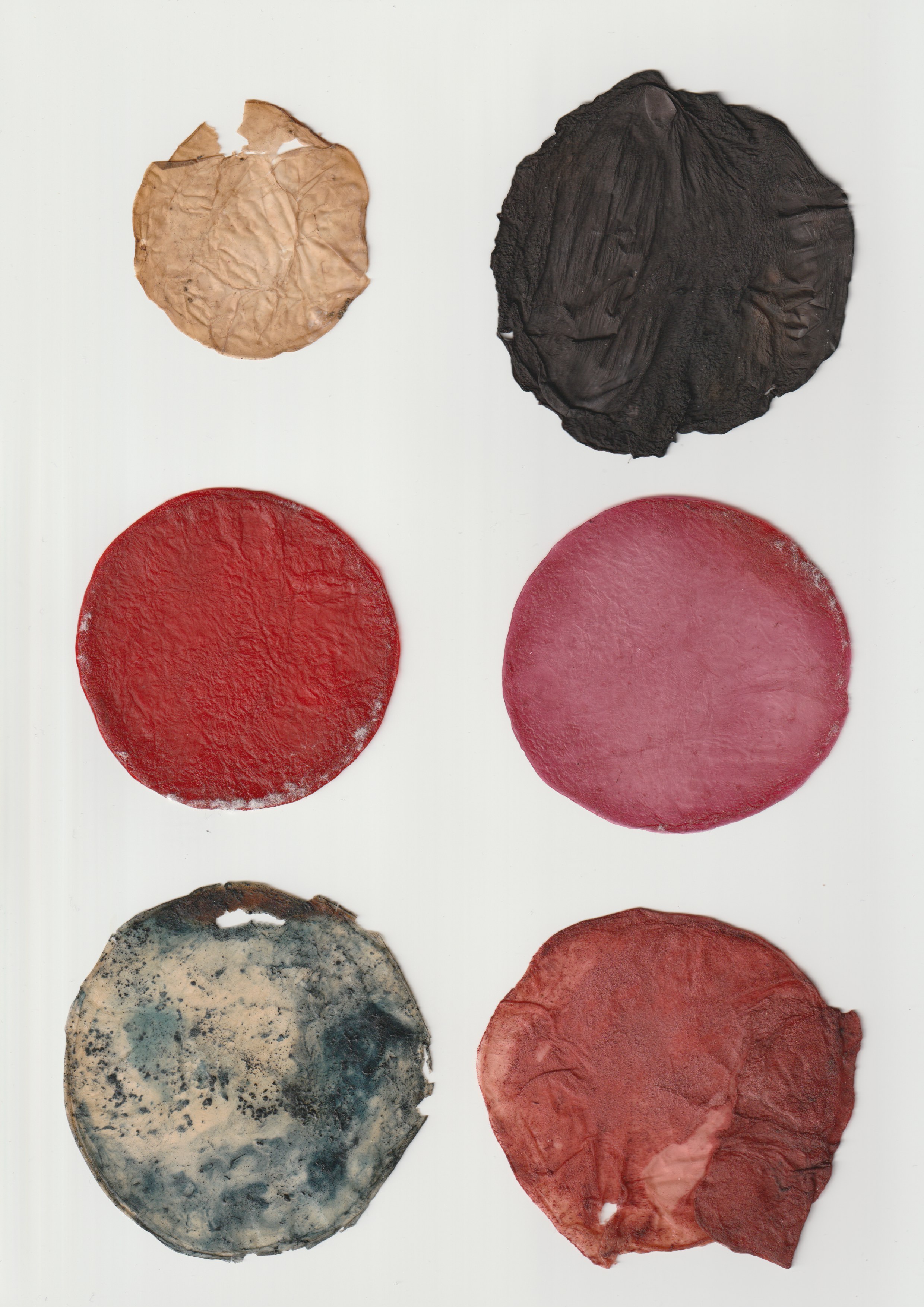

of textile is thereby envisioned. Adding natural colourants to the fermentation process creates vibrant

colours and expands the possibilities to design and rethink the common dyeing process.

Re-imagining the production of textile fibres by fermenting cellulose from bacteria in order to reduce

reliance on monocultures, deforestation and oil production. A machine is built to automately filament bacterial

cellulose in a micro-scale, and envision the scalability of the biofabrication.

“Although bacterial cellulose designs have so far been focused on sheet forms embodying nonwovens structures, there is little or no investigation into how the concepts of co-design and bio-manufacturing can directly form filaments. This leaves a wealth of material applications unexplored.“ (Morrow et al., 2023)

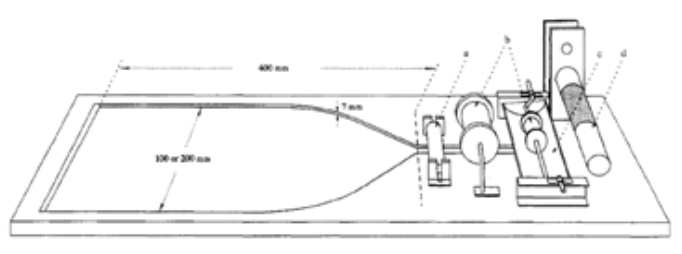

Hokkaido University, Sapporo, Japan 1997

Direct harvesting a BC filament

https://doi.org/10.1016/S0144-8617(97)00135-5

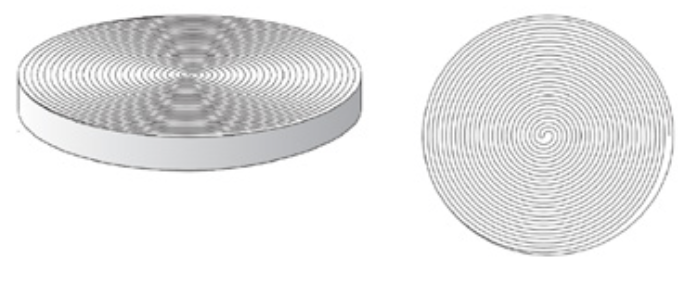

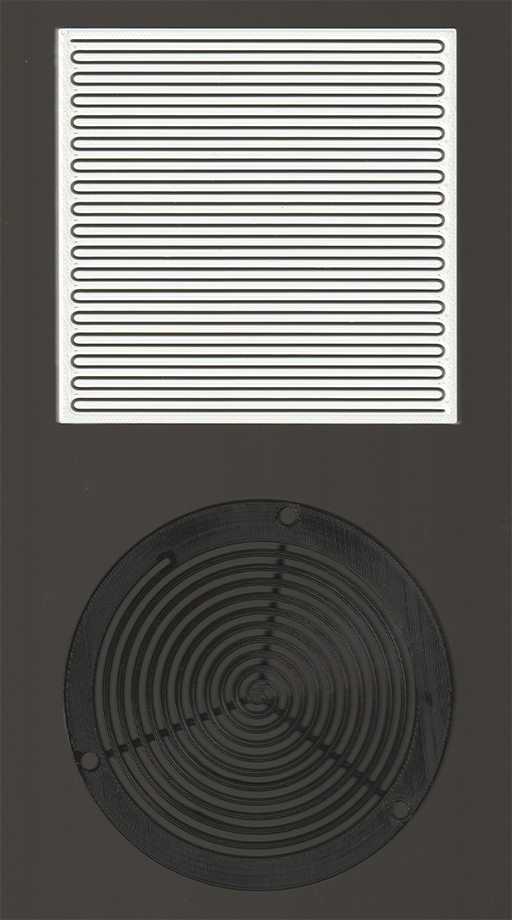

Royal College of Art, London, UK 2023

BC grown as a filament in a 3D printed spiral

https://doi.org/10.3390/ma16144893

Image by Stefen Reichert

JUN 2024

Award / Förderpreis, Rolf-Scheuermann-Stiftung

JUN 2024

Research Excellence Award, Institute for Applied Sciences / Institut für Angewandte Forschung (IAF)